BIO POLY NATURAL

$ 16.89

BIO POLY NATURAL

USES: Wood, Trim, Wood Staining, Wood Floors, Logs, Timbers, Fine Woodworking, Wood Finishing, Concrete Staining.

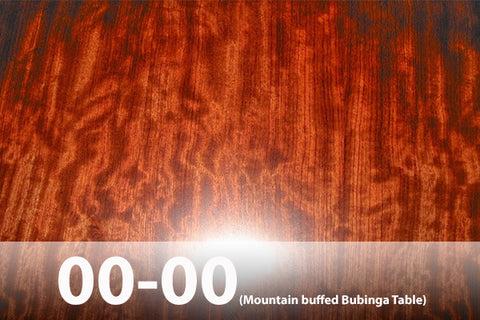

Bio Poly Natural is the best natural interior wood finish in it's class. It's a "bio polymer" that is a joy to work with, looks great and doesn't dry out like regular oils. This time tested finish saturates wood with the nourishment it craves. We love the excellent chatoyance (wood grain illumination) and it does it without toxic solvents! Sure, it's a gorgeous clear finish but we've never seen an easier to work with stain. Floor finishers love it as a clear buffing oil. Often it is used as a floor stain under NanoTech Clear 00 floor finish. Bio Poly Natural leaves wood lively and brings out the quilted depth of wood grain. It repels water and is easy to clean.

Bio Poly Natural is an excellent selection for USGBC LEED GREEN V4.1 HOMES and the wood finish of choice for many discriminating wood finishers who want a beautiful, natural clear oil finish.

Wood work inside this Southern Living Idea Home in Whisper Mountain is a great example (such as the door above). Check out Alchemy Design who put tastefully integrated country warmth and the joy of living into this home.

Conservancy and Preservation experts selected some truly exquisite materials with local craftsmen creating a masterpiece of sustainable living. Nothing beats rich oils and beeswax for beauty so we emphasize the beauty nature gave us.

This Balsam Preserve home used Earthpaint finishes throughout and was the first ever LEED Gold Certified house in NC. Bio Poly has been on so many cool projects over the years; the Timber Home Living article is a good place to get a feel for what it can do. The entire interior timber frame is all Bio Poly. The heart pine floor is buffed with Bio Poly and top coated with NanoTech Clear 00. This home was also able to achieve one of the first ever NC HEALTHY BUILT HOME GOLD Certifications.

WOOD FLOORS: Bio Poly is a fantastic wood finish and great on wood floors. It looks stunning and feels buttery smooth to the bare foot. The beeswax and super dense tree resins helps make it self polishing as it ages and wears. Bio Poly is perfect when buffed into low to medium traffic wood floors, like bedrooms or for high traffic floors that are rustic and need to be spot maintained. It is highly durable, water and stain resistant and easy to clean and maintain. Bio Poly with NanoTech topcoats are best for high traffic floors when an oiled look or stain is called for.

COATS TO APPLY: A sample pint is the best way to estimate since each wood requires a different amount to fully saturate the wood fiber cell.

Staining: Staining is typically done in one coat. Add more colorant to stain rather than doing multiple coats. This will save much time.

Hardwoods: Hardwood floors such as oak, hickory, Brazilian cherry will usually only take 2 coats of Bio Poly and then the final coat is just a buffing coat, topical.

Soft Woods: Softer woods like pine, fir, or reclaimed woods will tend to absorb more finish and need more coats. This is because the wood fiber cell is asking for more nourishment. Like a hungry baby, wood stops drinking when it's full. As any mother knows, it is best to let it get full. Once it stops taking nourishment into the wood then we know that the wood is fully saturated and ready for action.

One Coat: There are ways to force wood to accept only one coat of finish but we stopped doing that in 2007 once the need for full cellular saturation became more apparent. It's best to let wood decide when it's fully saturated.

Penetrating Natural Floor Finish Not Film Forming: Sometimes people want a film; a polyurethane alternative that will form a film on a floor, as a sacrificial barrier. Bio Poly is not a film forming floor finish. Bio Poly is not polyurethane. It is a natural penetrating floor finish that protects the wood by nourishing the wood fiber cell. It hardens and seals the wood fiber cell yet the micro spaces between wood cells remain breathable.

That Old Oil Based Polyurethane Look: The old oil based polyurethanes have a certain look but few people want to deal with the toxic things that come with it. Bio Poly top coated with NanoTech is the best way to achieve that old oil based floor finish look without the toxicity of many oil based polyurethanes. Bio Poly provides a deeply oiled illuminated wood grain and NanoTech forms a strong low odor, non toxic film on top.

Why We Call it Bio Poly Natural (previously NT): Biological Polymer Natural. Nature provides these ingredients biologically and we make it a polymer, so it is a naturally derived biological polymer. We call it Bio Poly. This is the best of all natural rubbing oils. It can be seen on some of the most beautiful woodworking and floors. It has all the advantages of a rich oil based finish or linseed oil but none of the petrochemical poison. Low quality linseed oil is pretty easy to get but the good stuff is rare. Very few quality linseed oil resins are made without petrochemical solvents. Bio Poly isn't made with petrochemical solvents and it doesn't dry out like linseed oil. It is a much more comprehensive formula; a natural bio polymer based wood finish.

NATURAL WOOD STAIN: Bio Poly is tinted with our zero voc colorant to create dozens of meticulously crafted wood stain colors. It is very easy to use and naturally avoids lap marks and blotchiness. We never worry about it drying out early or mid way through a stain job. The common approach to making stain is to dilute a little colorant and resin with a huge amount of cheap petrochemical solvent. A little resin, a little color, a lot of solvent. Unfortunately, this saturates the wood fiber cell too early before the real nourishment can get in. A dull look can result. We stopped using this diluted stain approach decades ago. Clearly it is not sustainable, it looks worse and is horrible to work with. Some really toxic stains look great but this usually requires the use of fast evaporating solvents to avoid the dead look of muted wood grain.

Bio Poly Natural is the opposite. It is full of resin wood loves. It nourishes as it stains. This reveals the depth of the wood grain and gives a lively look to stained wood. Up to a quart per gallon of Pure Citrus or Corn Solvent can be added if needed without compromising quality.

CONCRETE FLOORS: While we don't emphasize it enough, Bio Poly works outstanding on concrete floors. It is chosen for it's simplicity and ease of use as well as for it's durability and easy maintenance. Concrete is not easy to seal properly. Most diy'ers are shocked to learn the professional process for finishing concrete. Concrete is twice as hard to finish as a wood floor and it's basically made out of rock! It's nice to know that there is an easier way! THANK GOD! As long as the concrete is porous it can be coated. We use Earth Clean and Citric Acid to prepare concrete. Then we buff in Bio Poly. 2 coats is usually enough to seal it and stop it from being dusty. It also prevents moisture from penetrating, so water and spills come up easy, yet the concrete remains breathable. Some day, we will give full attention to concrete but until then, if you are thinking about doing your concrete floor a sample pint of Bio Poly is well worth the effort.

THEORETICAL COVERAGE:

New or Smooth Wood: 400-600 Sft / Gallon. (spread rate increases after the first coat, after the wood fiber cell is fully saturated.)

Staining Wood: 500-600 Sft / Gallon.

Rough Sawn or Dry Porous Wood: 200-400 Sft / Gallon. (Dilution usually not required for porous woods.)

DILUTION: 4:1 add one quart of Citrus or Corn Solvent per gallon, as needed.

APPLICATION: Product is a rubbing oil. It must penetrate the wood and cannot be left on the surface like a polyurethane. For floors this means it is Machine Buffed just like waxing a floor. For wood trim and such it is usually brushed or foam roller applied, thin and then wiped down with a dry rag or dry brush. Wood fibers absorb the nourishment they require and harden into a durable, gorgeous finish as can be seen in the product pictures. Sanding with fine grit sandpaper can increase sheen if desired or it can be applied to exhibit a flat finish.

CLEAN UP: Earth Clean and water.

REGULAR CLEANING: Earth Clean and water after a two week cure time.

SPOT MAINTENANCE: Can be spot maintained by wiping a coat onto the selected area and then wiping it off. Looking Glass Beeswax Polish can be used for spot maintenance or as a final polishing coat.

Check out Barlow Guitars. Ricky has worked out some really sharp finishes for his guitars. He uses a secret sauce of Bio Poly. I believe he also uses NanoTech for certain light toned woods.

Pine resin is notoriously resonant on wooden instruments. There are many instrument makers who use Bio Poly and our other wood finishes on guitars, pianos, dulcimers, clavinets, flutes, djembe, drums... I will try to add some of them here this year.